Manufacturing & Logistics

Delivering the future one solution at a time

Growth in e-commerce. Smart factories. Delivery robots. Digital transformation across the manufacturing and logistics industries is accelerating rapidly as the way we live rapidly changes. The resulting shift in demands of both consumers and businesses requires resilience, agility, and smart thinking.

Growth must be sustainable

Major companies engage NetZero strategies with strong ambitions to be achieved in a short period of time. Embrace this challenge as an opportunity to transform your Manufacturing and Logistics activities not only to pioneer a sustainable future but also to gain resilience and increase agility in an uncertain market.

Speed cannot sacrifice security

As digital manufacturing technology booms, swift product supply is no longer enough. Security must be at the forefront of transformation along each step of the process. Skilled tech talent will be central in balancing these demands — and that’s where Akkodis comes in.

Transform or get left on the shelf

Massive disruption in supply chains, low business visibility, and plateauing margins are pushing the manufacturing industry to accelerate the adoption of digital technologies. Companies must embrace technologies like AI, Cloud, Machine Vision, and Predictive Maintenance to remain relevant in the industrial and manufacturing sphere.

Companies must be ready for revolution

The fourth industrial revolution is upon us — driving a true transformation in technologies and processes that make industrial and production processes smart. Akkodis’ industrial automation engineers develop solutions for superior industrial processes and assist with all aspects of hardware and software design and implementation, including documentation, support, and standardization.

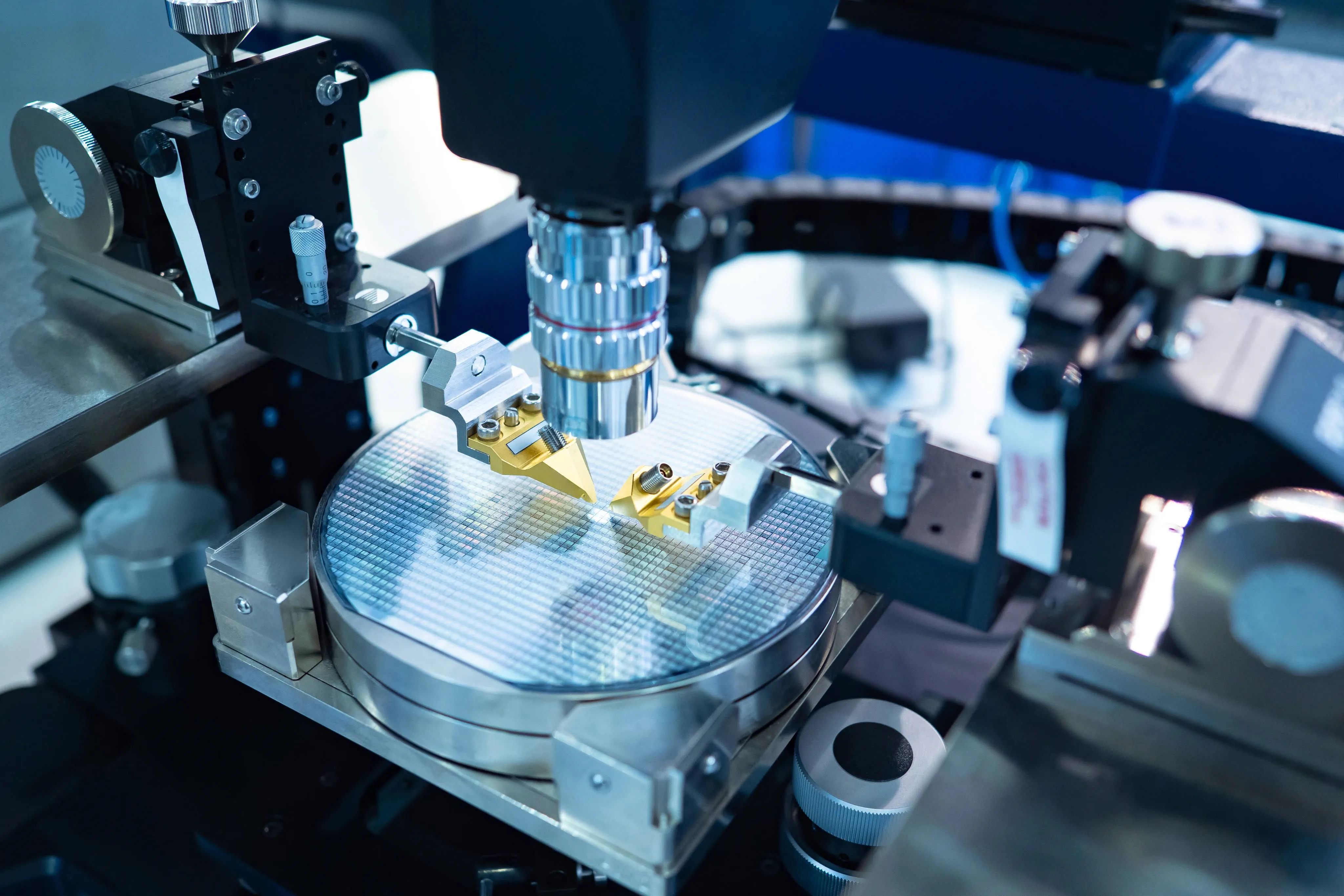

Electronics & Semiconductors

The semiconductor industry is at the core of the digital revolution. All major industries, such as communications, computing, healthcare, and manufacturing and logistics are dependent on the pace of semiconductor development to deploy their next-gen digital solutions.

Silicon Design

- FPGA Design & Architecture

- DFT (Design for Testing)

- Front-End & Verification

- Library Design

- Back-End Design

- Fabrication

Hardware Platforms

- Post Silicon Validation Reference Design Kits (RDK)

- RF/Antenna Design

- Development Platforms

Security

- Application Security

- Hardware Security

- IoT Security

- Mobile Security

Embedded Solutions

- System Design

- System Development

- System Manufacturing

- System Testing & Verification

Platform Software

- Platform Dev & Maintenance Platform Validation

- Android & Linux software

- Application software

- Firmware & Middleware Development

Support & Maintenance

- Silicon Lifecycle Management

- Predictive Maintenance

- System Performance

- Test & Quality Analytics

Industrial Manufacturing

Industry 4.0 is well underway and to survive in today’s digital landscape, every link in the supply chain must be optimized. Supply chain resiliency is fast becoming the focus for manufacturers to meet fluctuating demands and respond to future crises. Achieving this requires manufacturing solutions such as digital tools for real-time visibility and traceability as well as manufacturing execution systems (MES).

Hardware Platforms

- Post Silicon Validation

- Reference Design Kits (RDK

- RF/Antenna Design

- Development Platforms

Smart Factory Solutions

- Smart Manufacturing Platforms

- Smart PLM

- Asset Management

- Predictive Maintenance

Connected Solutions

- Internet of Things, Sensors

- Device Engineering

- Gateway Design & Development

- IoT Platform Development

Smart Engineering Solutions

- AR/VR in Manufacturing

- Robotics & Automation

- Advanced Analytics – AI/ML

- Additive Manufacturing

Manufacturing Engineering

- Plant Design & Engineering

- Simulation & Modelling

- Line & Fixture Design

- Manufacturing Automation

- CNC, CMM Engineering

- Quality Management

Value Engineering

- Value Analysis

- Reverse Engineering

- Product miniaturization

- Product Modernization

Logistics

Unlock efficiencies in production and logistics processes. With Akkodis, take advantage of real time planning solutions that optimize your entire supply, logistic and production chain – so you can make optimum decisions and pivot when necessary. Create redundancy and contingency plans so that the crucial work you do is not disrupted by supply chain issues or other events. Let’s future-proof your operations.

Production Planning solutions

- Design Assembly sequence and process planning

- Capacity planning, balancing and MTM analyzes (plan time analyses)

- Digital worker assistance systems (AR)

Intralogistics

- Intralogistics route optimization (based on AI)

- Material flow planning and simulation (digital twin)

- Optimize storage areas and picking process

- Optimize internal transport including AGV/FTS)

- Value stream analysis and process optimization according to lean management principles

Operational logistics

- Warehouse management

- Picking and packaging,

- Goods receipt and shipping,

- Internal transport,

- Production-related services, pre-assembly and assembly

Supply Chain

- Planning and support of relocations

- Outbound: Distribution and planning of the shipping network

- Inbound: Comparison and definition of delivery forms (conventional, JIT/JIS) and delivery frequencies

- Capacity and resource planning

- Complaint management

- Risk assessments along the supply chain

- Optimize logistics costs

Supplier management

- Supplier development

- Preventive and reactive supplier management

- Task force management

- Vulnerability analysis

- Tool management (analysis, tracking, auditing)

- Auditing VDA 6.3

- Market studies, potential analyses

- Supply chain risk management

- Capacity and bottleneck management

Planning of special load carriers (SLT)

- Concept planning, profiles

- Design detailed planning and simulation

- Supplier management

- Load carrier management

- Digital sample presentation

- Ergonomics, occupational safety, commissioning

- System trials, system testing

- Load carrier procurement / appointment tracking

- Quality goal

- Container planning (e.g. shopping baskets/special load carriers)

- Transport and route planning

Quality Management

- Production process and product release (PPAP/PPF)

- Process capability investigation (PFU)

- System analysis or equipment capability analysis (MSA)

- Advanced quality planning (APQP)

- Quality control / statistical process control (SPC)

- Audit: IATF 16949 / ISO 9001:2015 / ISO 14001

- Training and coaching on quality topics and methods

- Risk management / error management / complaint management